American Outback Buildings uses only quality american made fasteners in the construction of our buildings. We are the only company that can guarantee no roof leaks because we use our exclusive double-threaded HiGrip® roof screw. This unique screw allows the roof panels to remain tight and secure under all conditions.

It is very important to us that our clients have total satisfaction with the products and services that we supply. We strive to provide the highest quality in order to minimize problems with application and those associated with sub standard products.

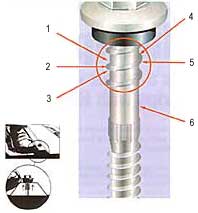

HiGrip®—The Better Roof Fixing

HiGrip® is a revolutionary design in roof fasteners that overcomes the traditional problems with crest fixing metal roofing to steel or timber.

Normal roofing screws often create an indent area around if the operator uses too much force while drilling

HiGrip® is a secondary thread located at the top of the shank under the washer face. During installation the thread of the HiGrip® carries the roof profile in an upward motion; while the washer face is carried into the fastener in the downward motion.

1.

The operator feels the thread bite, a clear signal to prevent over–drilling.

2. Restricts 'over–drilling' which leads to ponding or dimpling.

3. Prevents sheet moving down shank when roof is walked on.

4. Grips sheet to provide 'positive' joint with EPDM washer.

5. Extrudes metal around the fastener hole upwards making water ingress more

difficult.

6. Unthreaded shank prevents profile riding up during fixing.

Under

roof corrosion of roofing fasteners is a great hidden danger. All protective

coatings are subject to damage during installation. This damage is a scratching

by the roof sheeting along the shank of the fastener.

Corrosion—Fasteners ARE the weakest Link.

Fasteners made from normal alloys are subject to corrosion. Protective coatings

placed on fasteners follow the principles of "galvanic protection".

Fasteners are rated by the degree they resist corrosion.

Class 1—For general internal use where corrosion resistance is of minor

importance.

Class 2—For general internal use where significant levels of condensation

occurs.

Class 3—For general external use in mild and moderate industrial and

mild marine applications. This class is intended for roofing and cladding

screws in standard applications.

Class 4—A proposed class for external use in moderate and severe marine

environments up to 400 meters from the shoreline

Crest

Fixing

Crest fixing is more flexible—difficult to break the washer.

Fastener will flex with the sheet which eliminates the wear of expansion and

contraction.

No water damming around the fastener heads.

Saves Money! No Leaks! No Call Backs!

Pan

Fixing

Pan Fixing Leaks! Expansion and contraction causes leaks.

More Leaks! Fasteners spew, break or the washer flattens when hand fixing.

Water dams in the pan causing leaks.

Damming of pollutants, salt, acid rain, industrial fall–out which accelerates

corrosion.

American Outback Buildings, LLC. Lancaster, PA and Tampa, FL

Phone 717 464-2900 or Toll Free 1 877 723-2897